1. Intshayelelo

Njengesixhobo esingundoqo senkqubo yothutho lomgodi, indawo yokuphakamisa umgodi inoxanduva lokuphakamisa nokuthoba abasebenzi, intsimbi ekrwada, izixhobo, njl njl. Ukhuseleko, ukuthembeka kunye nokusebenza kakuhle kokusebenza kwayo kunxulumene ngokuthe ngqo nokusebenza kakuhle komgodi kunye nokhuseleko lobomi kunye nepropathi yabasebenzi.

Iinjini zemagnethi ezisisigxina zineengenelo ezininzi ezinje ngoxinaniso lwamandla aphezulu, ukusebenza kakuhle, kunye nengxolo ephantsi. Ukuzisebenzisa kwii hoists zemigodi kulindeleke ukuba kuphucule ngokubonakalayo ukusebenza kwezixhobo, ngelixa kuzisa amathuba amatsha kunye nemingeni ngokwemiqathango yoqinisekiso lokhuseleko.

2. Ukusetyenziswa kobuchwephesha bemagnethi esisigxina kwinkqubo yokuqhuba i-hoist drive

(1) .Imagnethi esisigxina umgaqo wokusebenza we-synchronous motor

Iimotor zemagnethi ezisisigxina zisebenza ngokusekwe kumthetho wokungeniswa kombane. Umgaqo ongundoqo kukuba xa inqanaba lesithathu elitshintshanayo langoku ligqithiswa kwi-stator winding, intsimi yemagnethi ejikelezayo iyenziwa, esebenzisana nemagnethi yemagnethi esisigxina kwi-rotor, ngaloo ndlela ivelisa i-torque ye-electromagnetic ukuqhuba i-motor ukujikeleza. Iimeko zesicelo se-hoist yam, i-motor kufuneka itshintshe rhoqo phakathi kweemeko zokusebenza ezahlukeneyo ezifana nomthwalo onzima, isantya esiphantsi kunye nomthwalo wokukhanya, isantya esiphezulu. Imagnethi esisigxina ye-synchronous motor inokuphendula ngokukhawuleza kunye neempawu zayo ezintle ze-torque ukuqinisekisa ukusebenza kakuhle kwe-hoist.

(2). Inkqubela phambili yetekhnoloji xa kuthelekiswa neenkqubo zokuqhuba zemveli

1. Uhlalutyo lokuthelekisa olusebenzayo

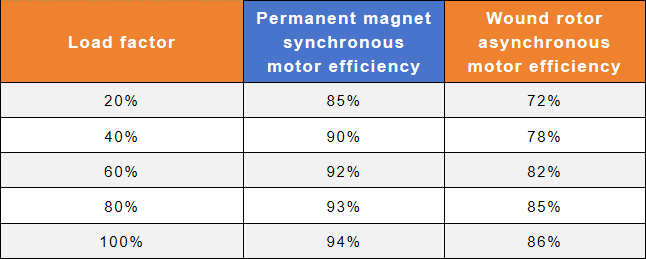

Ilahleko yeenjini ze-asynchronous ikakhulu ibandakanya ukulahleka kobhedu lwe-stator, ilahleko yobhedu lwerotor, ilahleko yentsimbi, ilahleko yomatshini kunye nokulahleka okulahlekileyo Ngokuthelekiswa kwedatha yovavanyo yokwenyani (njengoko kubonisiwe kuMfanekiso 1), phantsi kwamazinga omthwalo ahlukeneyo, ukusebenza kakuhle kwemagnethi esisigxina ye-synchronous motor iphezulu kakhulu kunelo le-rotor-rotor asynchronous motor.Kuluhlu lomthwalo we-50% - 100%, ukusebenza kakuhle kwemagnethi esisigxina ye-synchronous motor ingaba malunga ne-100% ye-synchronous motor, ephezulu kakhulu kune-100% ye-synchronous motor. ukunciphisa iindleko zokusetyenziswa kwamandla okusebenza kwexesha elide lokunyusa imigodi.

Umzobo 1: Ufaniso lokuthelekisa ijiko lemagnethi esisigxina yemotor ehambelanayo kunye nerotor yenxeba yeasynchronous motor

2. Ukuphuculwa kwezinto zamandla

Xa i-ronda-rotor asynchronous motor isebenza, amandla ayo ahlala ephakathi kwe-0.7 kunye ne-0.85, kwaye izixhobo ezongezelelweyo zembuyekezo yamandla asebenzayo ziyafuneka ukuhlangabezana neemfuno zegridi. Amandla ombane wemagnethi esisigxina ye-synchronous motor ingaba phezulu njenge-0.96 okanye ngaphezulu, kufutshane ne-1. Umba wamandla aphezulu awunciphisi kuphela umthwalo wamandla osebenzayo wegridi yamandla kwaye uphucula umgangatho wamandla wegridi yamandla, kodwa ukwanciphisa iindleko zombane wamashishini emigodi kwaye unciphisa iindleko zotyalo-mali kunye nokugcinwa kweendleko zembuyekezo ezisebenzayo.

(3). Impembelelo ekusebenzeni ngokukhuselekileyo kweehoists zam

1.Ukuqala kunye neempawu zokuqhomfa

I-torque yokuqala yeemotor ezisisigxina zemagnethi ezihambelanayo zigudile kwaye zilawuleka ngokuchanekileyo.Ngeli xesha lokuqalisa kwe-hoist yasemgodini, inokuphepha iingxaki ezinjengokushukuma kwentambo kunye nokwanda kokuguga kwesithungu okubangelwa yimpembelelo yetorque egqithisileyo xa iimotor zemveli ziqaliswa. Ukuqala kwayo okwangoku kuncinci kwaye akuyi kubangela ukuguquguquka okukhulu kwamandla ombane kwigridi yamandla, ukuqinisekisa ukusebenza okuqhelekileyo kwezinye izixhobo zombane emgodini.

Ngokubhekiselele kwi-braking, ii-motor ze-synchronous zemagnethi ezisisigxina zinokudityaniswa kunye ne-teknoloji yokulawula i-vector ephezulu ukufezekisa umgaqo ochanekileyo we-braking torque.Ngokomzekelo, ngexesha lenqanaba lokunyuka kwe-hoist, ngokulawula ubukhulu kunye nesigaba se-stator yangoku, i-motor ingena kwisimo sokuvelisa amandla e-braking, iguqulela amandla e-kinetic ye-hoist kwi-grid yokubuyisela amandla ombane kunye nokunyusa amandla. Xa kuthelekiswa neendlela zesiqhelo zokuqhobosha, le ndlela yokuqhobosha inciphisa ukunxitywa kwamacandelo e-brake mechanical, yandisa ubomi benkonzo ye-braking system, inciphisa umngcipheko wokungaphumeleli kweziqhoboshi ngenxa yobushushu obugqithileyo, kwaye iphucula ukhuseleko nokuthembeka kwe-hoist braking.

2.Ukungabikho kweempazamo kunye nokunyamezela iimpazamo

Ezinye iimotor ze-synchronous zemagnethi ezisisigxina zisebenzisa i-multi-phase winding design, ezifana nesigaba sesithandathu semagnethi esisigxina ye-synchronous motor.Xa isigaba somoya we-motor singaphumeleli, i-winding yesigaba esiseleyo sisenako ukugcina ukusebenza kwesiseko semoto, kodwa amandla okukhutshwa aya kuncitshiswa ngokufanelekileyo. phakamisa ukusuka ukushukuma embindini weshafti ngenxa yokusilela kwemoto, ngaloo ndlela kuqinisekisa ukhuseleko lwabasebenzi kunye nezixhobo. Ukuthatha inqanaba elithandathu lemagnethi esisigxina ye-synchronous motor njengomzekelo, ucinga ukuba enye yee-windings zesigaba ivulekile, ngokutsho kwethiyori yokuhanjiswa kwetorque ye-motor, ii-windings eziseleyo zesigaba ezintlanu zisenokubonelela malunga ne-80% yexabiso elithile le-motor ehambelana ne-torque ehambelanayo (ukugcina ixabiso elilinganisiweyo le-torque). i-elevator kunye nokuqinisekisa ukhuseleko.

3. Uhlalutyo lwemeko eyiyo

(1). Iimeko zesicelo kwimigodi yesinyithi

Umgodi wesinyithi omkhulu usebenzisa imagnethi esisigxina yemoto ehambelanayo ukuqhuba umazibuthe osisigxina injini yesynchronous enamandla alinganisiweyo eP=3000kw. Emva kokusebenzisa le njini, xa kuthelekiswa nemoto ye-asynchronous yenxeba lokuqala, phantsi komsebenzi ofanayo wokuphakamisa, ukusetyenziswa kwamandla ngonyaka kuncitshiswa malunga ne-18%.

Ngokubeka iliso kunye nohlalutyo lwedatha yokusebenza kweemoto, ukusebenza kakuhle kwee-motor synchronous zemagnethi esisigxina kuhlala kwinqanaba eliphezulu phantsi kweemeko ezahlukeneyo zokusebenza, ngakumbi kumazinga aphakathi kunye aphezulu omthwalo, apho inzuzo esebenzayo ibonakala ngakumbi.

(2). Amatyala eSicelo soMgodi wamalahle

Umgodi wamalahle ufake indawo yokuxhoma umgodi usebenzisa itekhnoloji yemagnethi esisigxina. Imagnethi yayo esisigxina ye-synchronous motor inamandla angama-800kw kwaye isetyenziselwa ikakhulu ukuphakamisa nokuthutha abasebenzi kunye namalahle. Ngenxa yomthamo olinganiselweyo wegridi yamandla emigodini yamalahle, amandla aphezulu ombane wemagnethi esisigxina wehlisa ngokufanelekileyo umthwalo kwigridi yamandla. Ngethuba lokusebenza, akukho kuguqulwa okuphawulekayo kwi-voltage yegridi yamandla ngenxa yokuqalisa okanye ukusebenza kwe-hoist, eyaqinisekisa ukusebenza okuqhelekileyo kwezinye izixhobo zombane kumgodi wamalahle.

I-4.Indlela yophuhliso lwexesha elizayo lwenjini yemagnethi esisigxina yokunyusa umgodi

(1). Uphando kunye nophuhliso kunye nokusetyenziswa kwezixhobo eziphezulu zemagnethi ezisisigxina

Ngokuqhubela phambili okuqhubekayo kwezinto zenzululwazi, uphando kunye nophuhliso lwezixhobo ezintsha ezinobuchwephesha ezisebenza ngokusisigxina ziye zaba ngulwalathiso olubalulekileyo kuphuhliso lobuchwepheshe bemagnethi esisigxina kwi-hoists yasemgodini. Umzekelo, isizukulwana esitsha sezinto ezinqabileyo zomhlaba ezisisigxina zemagnethi kulindeleke ukuba zifezekise impumelelo kwimveliso yamandla kazibuthe, amandla okunyanzela, uzinzo lobushushu, njl njl. iihoists; Uzinzo olungcono lobushushu luya kwenza ukuba iimotor zemagnethi ezisisigxina ziqhelane nemekobume engqongqo yasemgodini, efana nemigodi enobushushu obuphezulu; Amandla anamandla okunyanzeliswa aya kuphucula amandla emagnethi esisigxina echasene ne-demagnetization kwaye aphucule ukuthembeka kwemoto kunye nobomi benkonzo.

(2). Ukudityaniswa kobuchwephesha bolawulo olukrelekrele

Kwixesha elizayo, itekhnoloji yemagnethi esisigxina ye-hoists mine iya kudityaniswa ngokunzulu kunye netekhnoloji yolawulo olukrelekrele. Ngoncedo lobukrelekrele bokwenziwa, idatha enkulu, i-Intanethi yeZinto kunye nobunye ubugcisa obuphambili, ukusebenza ngobukrelekrele kunye nokugcinwa kweehoists kuya kufezekiswa.Ngokomzekelo, ngokufakela inani elikhulu labenzi boluvo kumacandelo aphambili eenjini zemagnethi ezisisigxina kunye nee-hoists, idatha yokusebenza inokuqokelelwa ngexesha lokwenyani, kwaye idatha inokuhlalutywa kwaye iqwalaselwe kusetyenziswa ukusilela kwe-artificial ye-artificial kunye nokuxilongwa kwangaphambili kwi-artificial algorithms ukulungiselela ukufezekiswa kwezixhobo zokwenziwa kwangaphambili. Kwangaxeshanye, inkqubo yolawulo yobukrelekrele inokwandisa ngokuzenzekelayo iiparitha zokusebenza zemoto, njengesantya, itorque, njl.njl., ngokweemfuno zokwenyani zemveliso yomgodi kunye nobume bokusebenza kwe-hoist, ukuze kufezekiswe injongo yokonga amandla kunye nokuphucula ukusebenza kakuhle kunye nokuphucula ukusebenza kakuhle kwemveliso kunye neenzuzo zoqoqosho lomgodi.

(3). Ukuhlanganiswa kwenkqubo kunye noyilo lweemodyuli

Ukuze kuphuculwe lula kunye nokugcinwa kokusetyenziswa kobuchwephesha bemagnethi esisigxina kwiindawo zokuxhoma umgodi, ukuhlanganiswa kwenkqubo kunye noyilo lwemodyuli iya kuba yintsingiselo yophuhliso.I subsystems ezahlukeneyo ezifana neenjini zemagnethi ezisisigxina, iinkqubo zokuqhafaza, kunye neenkqubo zokubeka iliso zokhuseleko zidityaniswe kakhulu ukwenza iimodyuli ezisebenzayo ezisemgangathweni.Xa kusakha umgodi okanye ukuhlaziya izixhobo, kufuneka ukhethe kuphela iimodyuli ezifanelekileyo ngokuhambelana neemfuno zofakelo olufutshane kunye nokufakwa kweemodyuli ezifanelekileyo kunye nofakelo olufutshane kunye neemodyuli zofakelo. kunciphisa iindleko zokwakha zobunjineli. Ukongeza, uyilo lwemodyuli luququzelela ukugcinwa kwezixhobo kunye nokuphuculwa. Xa imodyuli ingaphumeleli, inokutshintshwa ngokukhawuleza, ukunciphisa ixesha lokunciphisa kunye nokuphucula ukuqhubeka kwemveliso yomgodi.

5.Technical inzuzo Anhui Mingteng esisigxina umazibuthe motor

I-Anhui Mingteng eZisigxina-oomatshini bobuchwephesha kunye neZixhobo zoMbane Co., Ltd.https://www.mingtengmotor.com/).yasekwa ngo-2007. I-Mingteng ngoku inabasebenzi abangaphezu kwama-280, kuquka nabasebenzi abaqeqeshiweyo nabanobuchule abangaphezu kwama-50. Isebenza ngokukodwa kuphando kunye nophuhliso, imveliso kunye neentengiso ze-ultra-high-efficiency esisigxina yemagnethi yeemotor synchronous. Iimveliso zayo zigubungela uluhlu olupheleleyo lwe-high-voltage, i-low-voltage, i-frequency rhoqo, i-frequency frequency, eqhelekileyo, i-explosion-proof, i-drive ngqo, i-roller yombane, i-in-one machine, njl. Emva kweminyaka eyi-17 yokuqokelela kobugcisa, inamandla okuphuhlisa uluhlu olupheleleyo lweenjini zemagnethi ezisisigxina. Iimveliso zayo zibandakanya amashishini ahlukeneyo njengentsimbi, i-samente, kunye nemigodi, kwaye inokuhlangabezana neemfuno zeemeko ezahlukeneyo zokusebenza kunye nezixhobo.

UMing Teng usebenzisa ithiyori yale mihla yoyilo lweemoto, isoftware yoyilo lobuchwephesha kunye nenkqubo yokuyila imagnethi esisigxina ukulinganisa intsimi ye-electromagnetic, indawo yolwelo, indawo yobushushu, indawo yoxinzelelo, njl.

6. Isiphelo

Ukusetyenziswa kweenjini zemagnethi ezisisigxina kwizixhasi zemigodi kubonise ukusebenza okugqwesileyo ngokokhuseleko kunye nenkqubela phambili yetekhnoloji. Kwinkqubo yokuqhuba, ukusebenza kakuhle okuphezulu, amandla aphezulu kunye neempawu ezilungileyo ze-torque yeemotor ezisisigxina zemagnethi ezihambelanayo zibonelela ngesiseko esiluqilima sokusebenza okukhuselekileyo kunye nokuzinza kwe-hoist.

Ngohlalutyo lwemeko yokwenyani, kunokubonwa ukuba iinjini zemagnethi ezisisigxina ziye zafumana iziphumo ezimangalisayo ekusetyenzisweni kweehosti zemigodi kwiindidi ezahlukeneyo zemigodi, nokuba kukunciphisa ukusetyenziswa kwamandla, ukunciphisa iindleko zokugcinwa, okanye ukuqinisekisa ukhuseleko lwabasebenzi kunye nezixhobo. Ukujonga kwikamva, kunye nophuhliso lwezixhobo zemagnethi ezisebenza ngokusisigxina, ukudityaniswa kwetekhnoloji yolawulo olukrelekrele, kunye nokuqhubela phambili kodityaniso lwenkqubo kunye noyilo lwemodyuli, iimotor ezisisigxina zemagnethi zokuxhoma kwemigodi ziya kuzisa ithemba lophuhliso olubanzi, lufaka impembelelo enamandla kwimveliso ekhuselekileyo kunye nokusebenza ngokufanelekileyo koshishino lwemigodi. Xa kuqwalaselwa uphuculo lwetekhnoloji ye-hoist okanye kuthengwa izixhobo ezitsha, abathengi bemigodi kufuneka baqonde ngokupheleleyo amandla amakhulu eenjini zemagnethi ezisisigxina, kwaye ngokufanelekileyo basebenzise iimotor zemagnethi ezisisigxina ngokudityaniswa neemeko zokusebenza zokwenyani, iimfuno zemveliso, kunye nokomelela kwezoqoqosho kwemigodi yabo ukuphumeza uphuhliso oluzinzileyo lwamashishini emigodi.

Ilungelo lokushicilela: Eli nqaku lishicilelwe kwakhona kwikhonkco lokuqala:

https://mp.weixin.qq.com/s/18QZOHOqmQI0tDnZCW_hRQ

Eli nqaku alibonisi iimbono zenkampani yethu. Ukuba unezimvo ezahlukeneyo okanye iimbono, nceda usilungise!

Ixesha lokuposa: Dec-27-2024