Uhlalutyo oluBanzi lweNzuzo yokuTshintsha iiMoto eziAsynchronous kunye neeMoto ezisisigxina zeMagnet Synchronous.

Siqala kwiimpawu zemagnethi esisigxina ye-synchronous motor, edityaniswe nesicelo esisebenzayo ukucacisa izibonelelo ezibanzi zokukhuthaza imagnethi esisigxina ye-synchronous motor.

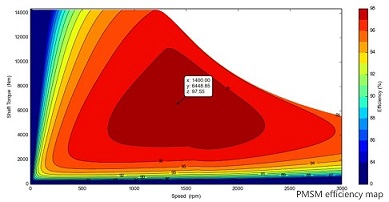

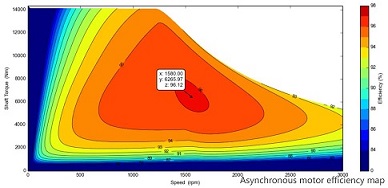

I-synchronous motor xa kuthelekiswa ne-asynchronous motor, izibonelelo zamandla aphezulu, ukusebenza kakuhle, iiparamitha ze-rotor zinokulinganiswa, isithuba esikhulu somoya we-stator-rotor, ukusebenza kakuhle kokulawula, ubungakanani obuncinci, ubunzima obulula, ulwakhiwo olulula, umlinganiselo ophezulu we-torque / inertia, njl., kwi-petroleum, kwishishini lemichiza, ilaphu elilula, imigodi, izixhobo zoomatshini be-CNC, iirobhothi kunye nezinye isantya esiphezulu sisetyenzisiwe torque), esebenza kakhulu kunye neMiniaturization.

Imagnethi esisigxina ye-synchronous motor ine-stator kunye ne-rotor. I-stator iyafana ne-asynchronous motor kwaye iqulethe i-wind-phase windings kunye ne-stator core. I-stator iyafana ne-asynchronous motor, equkethe i-windings emithathu kunye ne-stator core. I-rotor ixhotyiswe ngemagnethi yangaphambili (imagnethi) esisigxina, enokuseka indawo yamagnetic kwindawo ejikelezileyo ngaphandle kwamandla angaphandle, ukwenza lula ukwakhiwa kwemoto kunye nokugcina amandla.

Izibonelelo ezibalaseleyo zemagnethi esisigxina ye-synchronous motor

(1) Ekubeni i-rotor yenziwe ngeemagnethi ezisisigxina, ukuxinana kwemagnethi kuphezulu kwaye akukho nto yokuvuselela ifunekayo, ngaloo ndlela isusa ilahleko yokuvuselela. Xa kuthelekiswa ne-asynchronous motor, iyanciphisa i-excitation current ye-stator side winding kunye nobhedu kunye nokulahleka kwentsimbi yecala le-rotor, kwaye inciphisa kakhulu i-current reactive current. Ngenxa yokulungelelaniswa kwe-stator kunye ne-rotor enokubakho, akukho lahleko yentsimbi esisiseko kwi-rotor core, ngoko ke ukusebenza kakuhle (ngokunxulumene namandla asebenzayo) kunye nemeko yamandla (ngokunxulumene namandla asebenzayo) aphezulu kuneenjini ze-asynchronous. Iimotor zemagnethi ezisisigxina ze-synchronous zidla ngokuyilwa ukuba zibe namandla aphezulu kunye nokusebenza kakuhle nasemsebenzini womthwalo okhanyayo.

(2) Iimotor ezisisigxina zemagnethi ezihambelanayo zineempawu zoomatshini eziqinileyo kunye nokuchasana okunamandla nokuphazamiseka kwetorque yemoto okubangelwa lutshintsho lomthwalo. I-rotor core ye-magnetic esisigxina ye-synchronous motor inokwenziwa ibe yisakhiwo esingenanto ukunciphisa inertia ye-rotor, kwaye amaxesha okuqalisa kunye nokuyeka akhawuleza kakhulu kuneenjini ze-asynchronous. Umlinganiselo ophezulu we-torque / inertia wenza iimotor ezisisigxina zemagnethi ezihambelanayo zifaneleke ngakumbi ukusebenza phantsi kweemeko zokuphendula ngokukhawuleza kuneenjini ze-asynchronous.

(3) Ubungakanani beenjini ezisisigxina zemagnethi ezihambelanayo zincitshiswe kakhulu xa kuthelekiswa neenjini ze-asynchronous, kwaye ubunzima bazo buncitshisiwe. Uxinaniso lwamandla eenjini zemagnethi ezisisigxina ezineemeko ezifanayo zokulahla ubushushu kunye nezixhobo zokugquma zingaphezulu kokuphindwe kabini kuneemotor ezinenqanaba lesithathu le-asynchronous.

(4) Isakhiwo se-rotor silula kakhulu, kulula ukusigcina, kwaye siphucula ukuzinza kokusebenza.

(5) Ngenxa yamandla aphezulu afunekayo ekuyilweni kweenjini ze-asynchronous zesigaba sesithathu, kuyimfuneko ukugcina i-gap yomoya phakathi kwe-stator kunye ne-rotor encinci kakhulu. Kwangaxeshanye, ukufana kwesikhewu somoya kukwabalulekile ekusebenzeni okukhuselekileyo kunye nengxolo yokungcangcazela kwemoto. Ke ngoko, iinjini ze-asynchronous zineemfuno ezingqongqo zokumila kunye nokunyamezelana kwesikhundla samacandelo kunye nokuhlangana kwendibano, kwaye kukho idigri ezimbalwa zenkululeko yokukhetha ukuvunywa. Isakhelo esikhulu iimotor ze-asynchronous zihlala zisebenzisa iibheringi ezithanjiswa ngeebhafu zeoyile, Kuyimfuneko ukongeza ioyile yokuthambisa ngaphakathi kweeyure zokusebenza ezichaziweyo. Ukuvuza kweoyile okanye ukuzaliswa kwangethuba kwigumbi leoli kunokunyusa ukusilela kokuthwala. Ekugcinweni kweenjini ze-asynchronous zesigaba esithathu, ukuthwala i-akhawunti yokugcinwa kwenani elikhulu. Ukongezelela, ngenxa yobukho be-induced current kwi-rotor ye-asynchronous motors ezithathu, umba wokubola kombane we-bearings uye waba nenkxalabo kubaphandi abaninzi kwiminyaka yamuva.

(6) Iimotor zemagnethi ezisisigxina azinazo iingxaki ezinjalo. Iingxaki eziyeleleneyo ezibangelwa ngumsantsa womoya omkhulu weemotor ezilungelelanisiweyo zemagnethi kunye nomsantsa omncinci womoya wezi njini zeasynchronous azicacanga kwiimotor ezihambelanayo. Kwangaxeshanye, iibheringi zeenjini zemagnethi ezisisigxina zisebenzisa iibheringi ezigcotyiweyo ezinezigqubuthelo zothuli. Iibheringi zitywinwe ngexabiso elifanelekileyo legrisi yokuthambisa ekumgangatho ophezulu kumzi-mveliso, enokugcinwa simahla ubomi bonke.

Epilogue

Ngokwembono yeenzuzo zoqoqosho, iimotor ezisisigxina zemagnethi ezilungelelanisiweyo zifaneleke ngakumbi ukuqalisa okunzima kunye neemeko zokusebenza okulula. Ukukhuthaza ukusetyenziswa kweenjini zemagnethi ezisisigxina kuneenzuzo ezintle kwezoqoqosho nezentlalo, kwaye kubaluleke kakhulu kugcino lwamandla kunye nokunciphisa ukukhutshwa. Ngokuphathelele ukuthembeka kunye nozinzo, iimotor ezisisigxina zemagnethi ezihambelanayo nazo zinezibonelelo ezixabisekileyo. Ukukhetha iimotor zemagnethi ezisebenzayo ezisebenza ngokugqibeleleyo kukutyalomali lwexesha elinye kunye nenkqubo yenzuzo yexesha elide.

Emva kweminyaka eyi-16 yokuqokelela iteknoloji, Anhui Mingteng Permanent-Magnetic Machinery & Electrical Equipment Co., Ltd inamandla R & D kuluhlu olupheleleyo lweenjini ezisisigxina umazibuthe, egubungela amashishini ezahlukeneyo ezifana intsimbi, isamente, kunye nemigodi yamalahle, kwaye unokuhlangabezana neemfuno iimeko ezahlukeneyo zokusebenza kunye nezixhobo. Xa kuthelekiswa neenjini ze-asynchronous zengcaciso efanayo, iimveliso zenkampani zinokusebenza okuphezulu, uluhlu olubanzi lokusebenza kwezoqoqosho, kunye neziphumo ezibalulekileyo zokonga amandla. Sijonge phambili kumashishini amaninzi nangakumbi asebenzisa iimotor zemagnethi ezisisigxina ngokukhawuleza ukunciphisa ukusetyenziswa kunye nokunyusa imveliso!

Ixesha lokuposa: Nov-08-2023